Wet wipes, as a convenient and hygienic cleaning product, are widely used in a variety of fields such as personal care, household cleaning and healthcare. As consumers demand higher and higher quality of wipes, performance optimisation of wipes has become an important focus for manufacturers in the research and development process. The performance of wipes does not only depend on the production process, but also on the selection and matching of key raw materials, which directly affects the use of wipes and their market performance. Therefore, the selection of raw materials is particularly important when optimising the performance of wipes, and the following are some key raw material considerations.

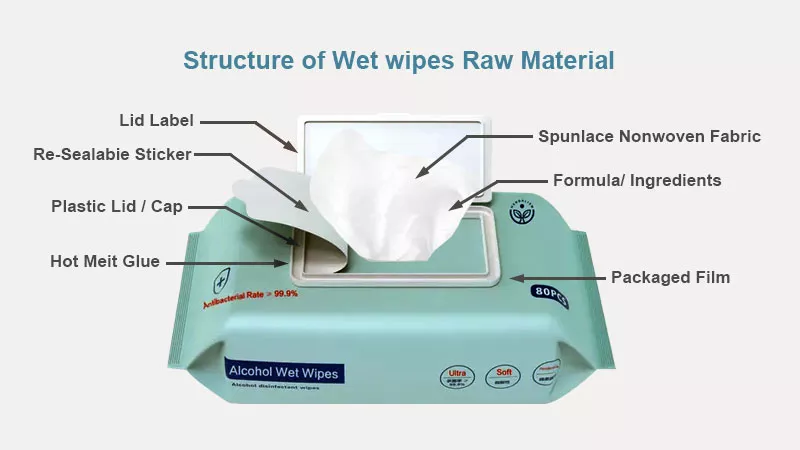

Firstly, the base material of wipes is the core of wipes performance. As the main base material of wipes, the performance of nonwoven fabrics directly determines the softness, durability and water absorbency of wipes. Commonly used nonwoven materials in the market are spunbond nonwoven, meltblown nonwoven, needle-punched nonwoven, etc., each with different characteristics. Spunbond nonwoven fabrics have better strength and durability, and are suitable for wipes products that require higher abrasion resistance and thickness; while meltblown nonwoven fabrics have better filtration properties, and are suitable for products with high cleanliness requirements, such as cleaning wipes and baby wipes. According to the different uses of wipes, choosing the right nonwoven material is the first step to improve the performance of wipes.

Secondly, the formulation of the wetting solution for the wipes is also an important factor in optimising the performance of the wipes. The role of the wetting liquid is to maintain the wetness of the wipes, and at the same time, it has the functions of cleaning, disinfection, moisturising and so on. Typically, a moisturiser consists of water, a humectant, a detergent, a biocide and other ingredients. Water is the base ingredient of a moisturiser, while humectants (e.g. glycerine, propylene glycol, etc.) help to keep the skin moist and avoid dryness. The choice of cleanser is also crucial; the right cleanser can effectively remove stains and bacteria without irritating the skin. Biocides are used to increase the antimicrobial properties of the wipes, especially important in medical and sterilising wipes. Adjusting the ratio of ingredients in the moisturiser can make the wipes cleaner, more antibacterial and more comfortable while remaining moist.

In addition to non-woven fabrics and moisturisers, fragrances and additives are also key raw materials for wipes. Fragrances not only enhance the experience of using wipes and give users a pleasant sensory experience, but also help mask the odour of some detergents or other ingredients. However, fragrances need to be used with caution, especially for users with sensitive skin, as certain fragrances may cause allergic reactions. Therefore, choosing non-irritating natural or hypoallergenic fragrances is critical to the success of a wipes product. In addition, certain wipes products may include additives such as vitamins and plant extracts to enhance the skin care benefits of the wipes. The choice and mix of these additives not only affects the market positioning of wipes, but also directly influences consumers' purchasing decisions.

Email:ecosanequip@gmail.com

Add: Henan Communication Industry Area, Jingbei 3rd Road, Zhengzhou, Henan, China