Tissue machines have become an integral part of the paper industry, revolutionizing the way we produce everyday products, from toilet paper to facial tissue. Why are these machines so popular? In this article, we’ll explore the main reasons why tissue machines are indispensable in today’s market, including their efficiency, versatility, and how they meet the growing demand for hygiene products. Let’s take a deeper look at the mechanisms behind their rise in popularity and why the paper industry is investing in them.

1. Improved Production Efficiency: One of the main reasons for the surge in popularity of tissue machines is their ability to automate production on a large scale. These machines can produce large quantities of tissues quickly, reducing the need for labor and significantly reducing production costs. Automation ensures consistency, faster turnaround times, and the ability to meet high demand levels without compromising quality.In fact, modern tissue machines can operate 24/7 with minimal downtime, making them an essential tool for companies to meet the growing global demand for hygiene products.

2. Sustainable Practices: As more consumers and businesses adopt eco-friendly practices, tissue machines have also adapted to this shift. Manufacturers have made significant progress in reducing the environmental impact of tissue production. Many modern tissue machines use recycled paper, minimizing waste and using less energy than older models.

3. Product Variety: From premium toilet paper to industrial tissue, the versatility of tissue machines is another reason they are so popular. Modern tissue machines are able to produce a wide variety of paper products, each tailored to specific consumer needs.Whether it is the softness of facial tissue or the durability of industrial tissue, tissue machines can adjust production parameters to produce tissue products of different textures, sizes and types. This flexibility allows manufacturers to meet different market needs, whether it is a luxury brand for high-end consumers or a cost-effective solution for large enterprises.

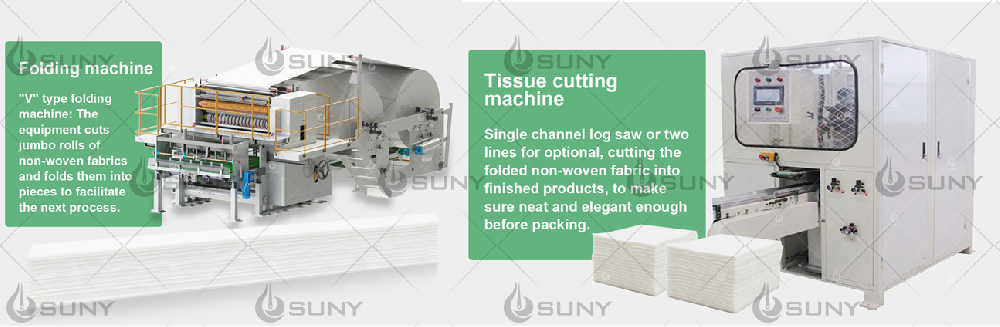

4. Improved Product Quality: In an industry such as tissue production, quality is everything. Consumers expect products to be soft, absorbent and durable. Tissue machines are carefully designed to ensure precision in each roll of paper, maintaining consistent thickness, strength and texture.The advanced technology of tissue machines includes features such as high-speed dryers, precision cutting and automatic packaging to guarantee a first-class product. For businesses, this means lower defect rates, fewer returns, and ultimately higher customer satisfaction.

5. Cost-effective production: Tissue machines offer huge potential for long-term savings and profits. As tissue machines streamline production processes and reduce operating costs, manufacturers can produce large quantities of cost-effective tissues at a very low cost.These machines have minimal waste, high efficiency, low energy consumption, and a high return on investment. Lower production costs mean that companies can produce high-quality and affordable tissues, thereby increasing competitiveness and profitability.

6. Technological advancements: The popularity of tissue machines also stems from their continued technological development. With innovations in artificial intelligence, machine learning, and data analytics, modern tissue machines are smarter than ever before. These machines can monitor production quality and even optimize speed to ensure that tissue production is always running at peak efficiency.

Email:ecosanequip@gmail.com

Add: Henan Communication Industry Area, Jingbei 3rd Road, Zhengzhou, Henan, China