The alcohol swab manufacturing industry has seen steady growth, driven by demand from healthcare facilities, laboratories, and hygiene-conscious consumers. For businesses entering this sector or scaling production, understanding the costs and returns of machinery for alcohol swab is essential. This article explores the factors influencing equipment pricing, compares automation levels, and provides a framework for calculating ROI—without relying on volatile data.

1. Types of Machinery and Cost Considerations

Alcohol swab production typically requires three types of equipment:

a) Fully Automated Systems

Function: High-speed, end-to-end production with minimal human intervention.

Cost Range: Premium pricing due to advanced features like AI-driven quality control and integrated sterilization.

Best For: Large manufacturers prioritizing volume, consistency, and long-term labor savings.

b) Semi-Automatic Machinery for Alcohol Swab

Function: Combines manual input (e.g., material loading) with automated sealing and packaging.

Cost Range: Mid-tier, appealing to startups or smaller operations with moderate output goals.

Best For: Businesses balancing budget constraints with scalability.

c) Sterilization and Compliance Equipment

Function: Ensures products meet medical-grade standards (e.g., FDA, ISO certifications).

Cost Range: Varies by technology (UV, chemical, or heat-based systems) and regulatory requirements.

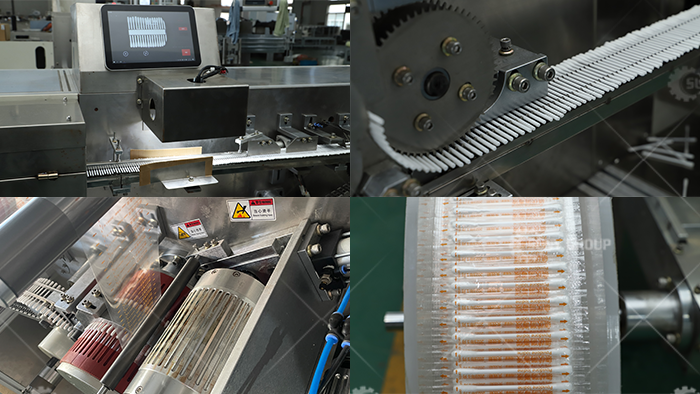

Fully Automated Machinery for Alcohol Swab Line

While exact figures fluctuate, these factors universally impact machinery costs:

Automation Level: Fully automated systems command higher prices than semi-automatic or manual alternatives.

Production Capacity: Machines designed for high-volume output (e.g., thousands of swabs per hour) cost more than low-capacity models.

Customization: Tailored solutions (e.g., adjustable swab sizes or alcohol saturation levels) increase upfront expenses.

Brand Reputation: Established manufacturers often price equipment higher due to proven reliability and after-sales support.

Example Comparison:

A high-speed automated line from a globally recognized brand may cost significantly more than a semi-automatic system from a regional supplier, but it reduces long-term labor and error-related expenses.

To evaluate machinery investments, consider these non-numerical frameworks:

a) Labor vs. Automation Trade-Off

Automated systems minimize manual labor but require higher initial investment.

Semi-automatic machines lower upfront costs but increase per-unit labor expenses over time.

b) Production Scalability

High-capacity machinery supports future growth, avoiding costly upgrades.

Smaller systems may limit output during demand spikes, risking lost revenue.

c) Maintenance and Downtime

Premium machines often include extended warranties and remote diagnostics, reducing unplanned downtime.

Budget equipment may incur higher repair costs and disrupt production schedules.

Beyond the sticker price, factor in:

Regulatory Compliance: Certification fees, audits, and facility upgrades to meet medical standards.

Training: Operator skill development to maximize machinery efficiency and safety.

Energy Consumption: High-speed systems may increase utility bills, affecting long-term ROI.

Maintenance Contracts: Preventive servicing agreements to avoid abrupt breakdowns.

Consider a hypothetical manufacturer transitioning from manual to semi-automatic production:

Challenge: Rising labor costs and inconsistent output quality.

Solution: Invest in mid-tier machinery with modular upgrades.

Outcome: Reduced labor dependency, improved product uniformity, and readiness to scale.

While specific ROI timelines depend on market conditions, this approach highlights the importance of aligning equipment choices with business goals.

Audit Production Needs: Define current and projected output volumes.

Prioritize Flexibility: Choose machinery for alcohol swab that adapts to evolving product designs (e.g., swab shapes or packaging).

Evaluate Supplier Support: Opt for vendors offering training, maintenance, and software updates.

Phase Investments: Start with semi-automatic systems and upgrade incrementally as demand grows.

Investing in alcohol swab manufacturing machinery involves balancing upfront costs, operational efficiency, and regulatory compliance. While automated systems offer long-term savings through reduced labor and errors, semi-automatic machines provide an accessible entry point for smaller businesses. By focusing on scalability, supplier partnerships, and lifecycle costs—rather than volatile price data—manufacturers can make informed decisions that align with their financial and production goals.

Always request customized quotes and trial demonstrations to assess how specific machinery performs in your facility. This hands-on approach, paired with strategic planning, ensures a sustainable path to profitability in the competitive hygiene products market.

Email:ecosanequip@gmail.com

Add: Henan Communication Industry Area, Jingbei 3rd Road, Zhengzhou, Henan, China